Removing PFAS and contaminants from leachate

A leachate treatment plant using a combination of engineering and nature-based solutions to remove contaminants and PFAS from landfill leachate.

- Removes up to 100% of PFAS contaminants

- Highly energy efficient

- Closed loop system – treatment and reuse onsite

- No chemical dosing and very low consumables used

Project Summary

In 2022, the Water & Carbon Group commissioned the Shoal Bay Leachate Treatment Plant, with client City of Darwin. The plant is a world-first advancement in treating per- and poly- fluoroalkyl substances (PFAS), along with a host of other harmful substances and impurities found in landfill leachate.

The leachate plant is unique in that it uses a combination of engineering and nature-based solutions and our patented LEEF System® foam fractionation technology for PFAS removal.

50

Project Summary

In 2022, the Water & Carbon Group commissioned the Shoal Bay Leachate Treatment Plant, with client City of Darwin. The plant is a world-first advancement in treating per- and poly- fluoroalkyl substances (PFAS), along with a host of other harmful substances and impurities found in landfill leachate.

The leachate plant is unique in that it uses a combination of engineering and nature-based solutions and our patented LEEF System® foam fractionation technology for PFAS removal.

Challenge

The Shoal Bay Waste Management Facility receives more than 180,000 tonnes of waste each year from 164,000 residents who live in the greater Darwin region (Northern Territory, Australia). Due to the region’s high rainfall, the facility also generates large volumes of leachate that must be treated and kept out of the surrounding environment, which includes ecologically important habitat.

Leachate is a complex, odorous and harmful liquid generated in landfills which is generated after rainwater or groundwater passes through waste materials that contain heavy metals, ammonia, and other substances created from putrefying waste.

PFAS are a synthetic group of chemicals that have been manufactured for use in a wide range of consumer and commercial products. As these products reach the end of their useful life, they are discarded, finding their way into landfills, becoming an issue for the operators of these facilities.

Solution

The WCG team designed and engineered a PFAS treatment solution after finding that there was nothing ‘off-the-shelf’ that was feasible for leachate. The result was the LEEF System®. This patented process has been installed as a key component of the leachate treatment plant, specifically to remove PFAS from the leachate.

The LEEF System® uses foam-fractionation to remove up to 100% of PFAS contaminants. Foam fractionation takes advantage of the way PFAS attach to air bubbles. By introducing controlled amounts of air into the system in a specific manner, the air bubbles rise to the top and then are skimmed off, and the highly concentrated PFAS contaminants are removed.

In full production the plant is processing up to 140,000 litres of leachate daily, with its capacity being readily scaled to meet higher demands or scaled down as needed. Other key benefits of the LEEF System at Shoal Bay:

- Remove up to 100 per cent of PFAS contaminants

- No chemical additives

- Operates with low energy consumption and minimal operational requirements

- Eliminates the need for costly pre-treatment such as filtration or coagulation (in contrast to more conventional methods like reverse osmosis or activated carbon)

- Continuous flow system

- Designed to be both scalable and modular, allowing for easy customisation

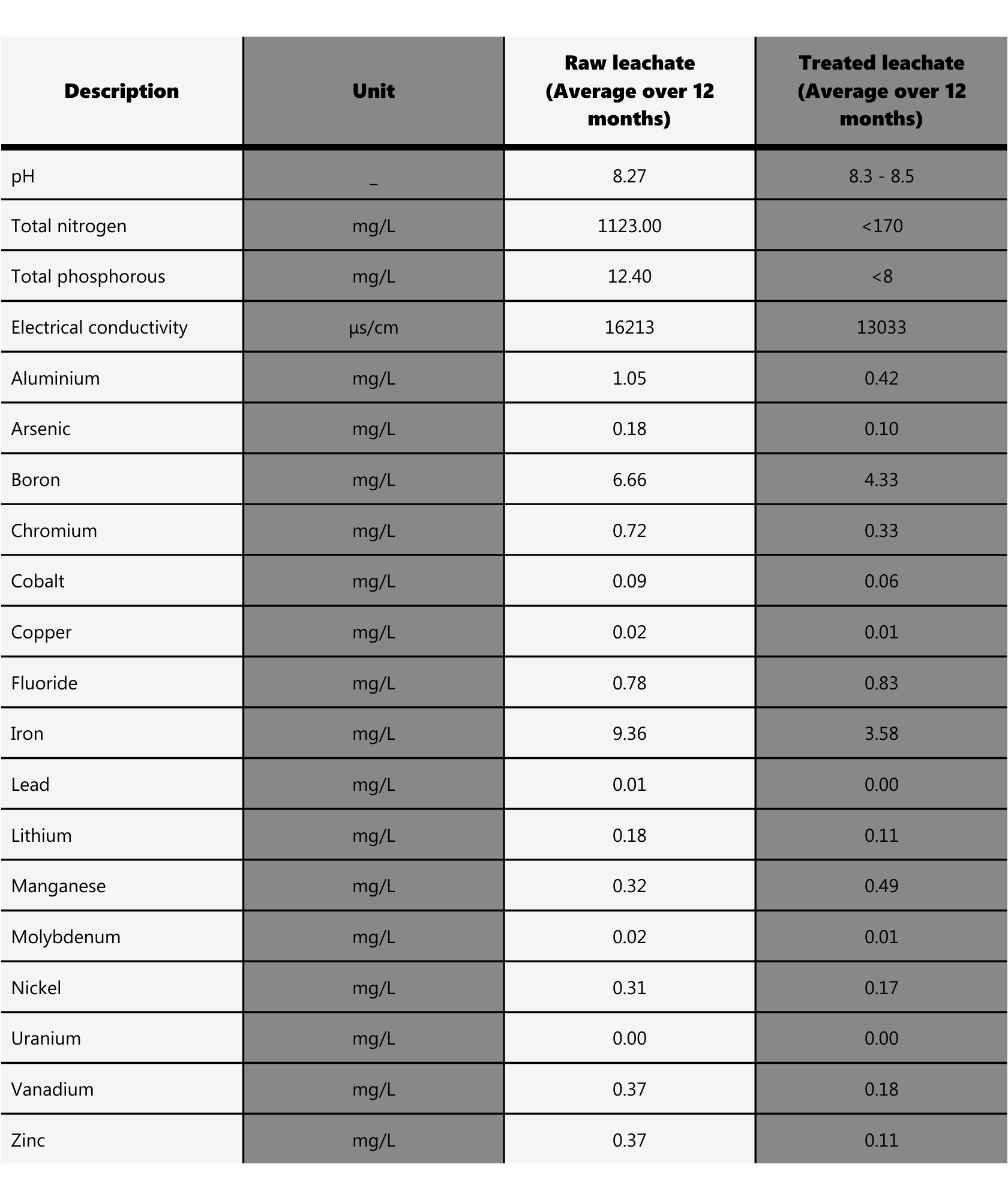

In addition to removing PFAS, the plant integrates biological and ecological treatment processes to remove the balance of contaminants. Treated effluent from the LEEF System® is further processed via a biological treatment plant which uses microbes for nutrient removal and a wetland treatment for a final polishing stage to remove residual nutrients and heavy metals.

Finally, the treated leachate is used to irrigate a Vetiver grass crop. This is a process of phytoremediation, whereby plants are used to clean up the remaining contaminates. The Vetiver also stabilises the banks of the capped landfill cells. Evapotranspiration results in a zero liquid discharge closed loop treatment solution.

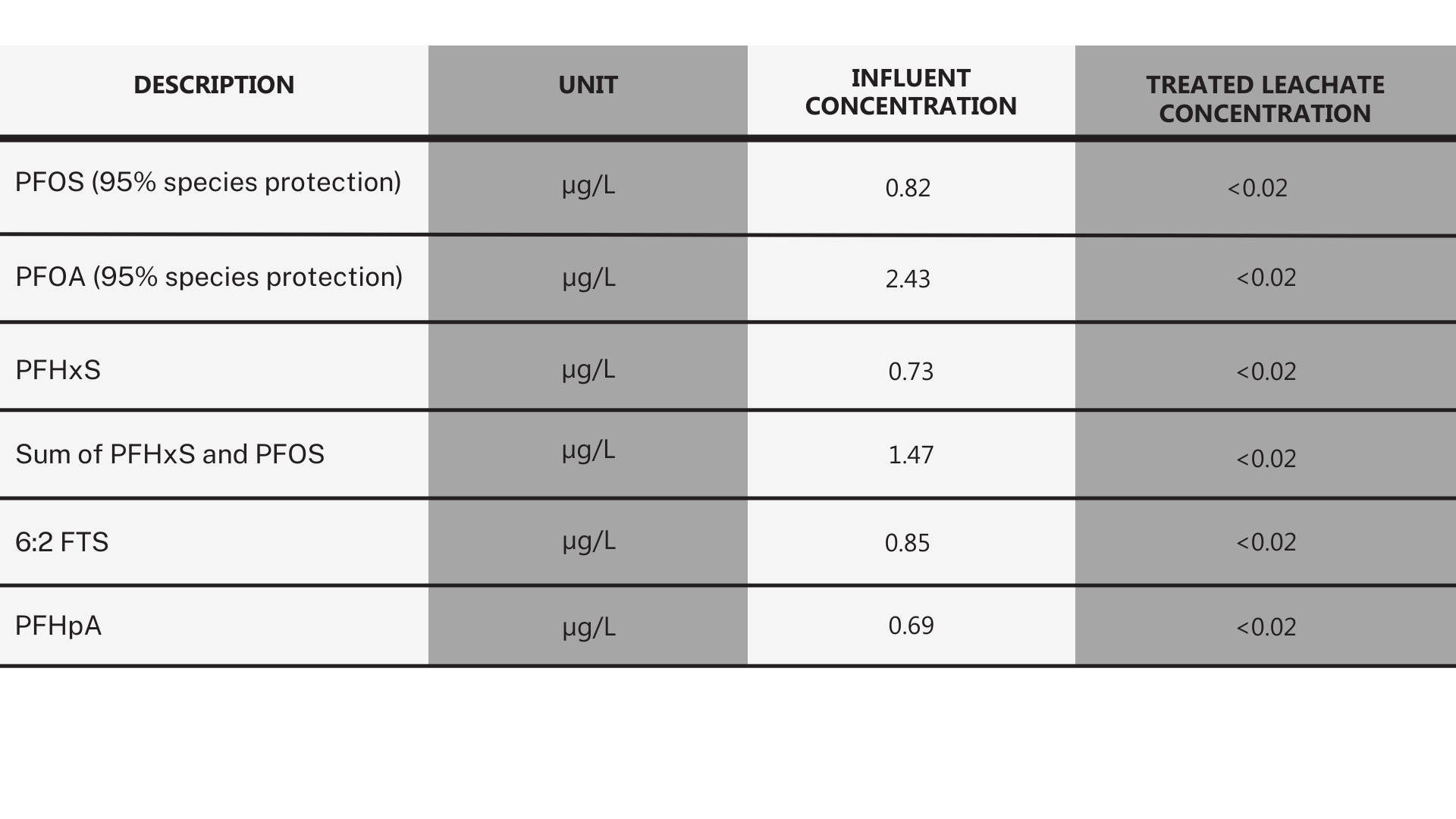

Results

Results indicate that regulatory requirements are being met and exceeded, with up to 100% of PFAS contaminants being removed.

Client Testimonials

“Leachate, and PFAS within leachate, is an issue for all waste management facilities. Our commitment at the City of Darwin was to tackle these contaminants using an innovative approach to protect the local environment and the community. Investment in this innovative leachate & LEEF System PFAS treatment technology has enabled City of Darwin to treat large volumes of leachate generated in a high rainfall environment. We’re proud to say that this achievement positions Darwin as a global leader in leachate and PFAS treatment."

- Nick Fewster, Executive Manager of Environment and Waste Services, City of Darwin

“City of Darwin is leading the country with this technology, and I am proud that the Shoal Bay Waste Management Facility features an Australian-first approach in reducing the threat of PFAS. Leachate and PFAS are problems faced by all Australian waste management facilities, and we now have a solution that protects our environment and meets the requirements of the Northern Territory Environment Protection Authority.”

- Lord Mayor Kon Vatskalis, City of Darwin

Contact Us

For more information about our wastewater, leachate, and PFAS solutions contact us and we will be in touch.

Linc Symons, Site Operations Manager at the Shoal Bay Leachate Treatment Plant in Darwin, Australia, talks about how the plant is using engineered and biological solutions to remove contaminants from leachate.

The Water & Carbon Group, together with the City of Darwin, opened the Shoal Bay Leachate Treatment Plant in 2022.